The automatic HDPE bottle blowing machine employs advanced stretch blow molding technology and is designed specifically for the production of high-density polyethylene containers. Combining high efficiency, precision, and energy efficiency, this blow molding machine is suitable for producing a wide range of industry-standard bottle shapes.

● Introducing advanced technology from Germany, Italy, japan etc.Involving advanced design and production of super large-scale blow-molding machine and engineering managementcapability. Holding over 40 items Patent Technologies.

● Special design can be made to order to for visistipe(VS) or two colors(TC) or two layers(TL) bottles.

● DHD-2L blow molding machine is a double station machine, and suitable for producing high quality container with medium output with from one to six fold die head, for use in the packaging of petroleum, cosmetics, chemicals, pharmaceuticals, food, toys and auto-parts.

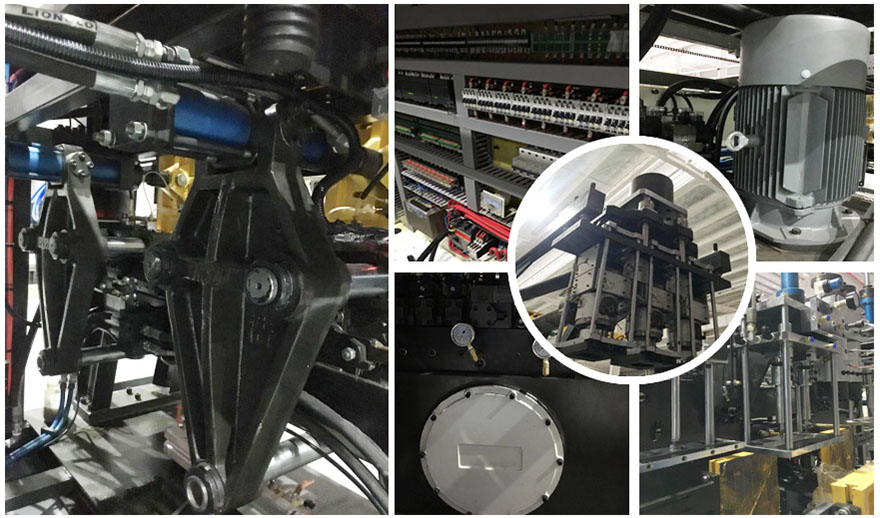

● The clamping system is a high-precision single-station linear guide, extrusion system using a hard gear reducer and inverter imported from Japan.

● The die head system adopts central-incoming extrusion die made of special steel, imported hydraulic valve and seal parts with proportional control valve.

● The control system consists of PLC and Human-machine interface imported from Japan, an automatic temperature control module and imported electrical part.

Food & Beverage: Mineral water/juice/dairy packaging/Edible oil/condiment containers.

Cosmetics & Pharma: Shampoo/cosmetic packaging/Medicine/disinfectant containers.

Industrial: Lubricant/chemical bottles/Pesticide/detergent packaging.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign