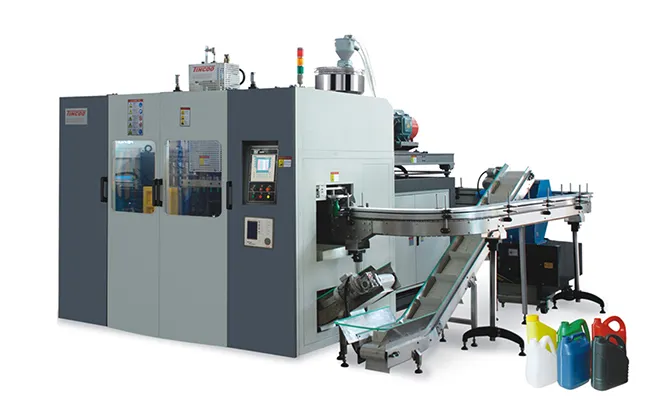

In today’s ever-changing manufacturing era, efficiency, precision and automation have become indispensable keywords on the production line. The double station extrusion blow molding machine is an outstanding representative of this trend.

The biggest highlight of the double station extrusion blow molding machine is its unique double-station design. This design enables the machine to perform two blow molding operations at the same time, greatly improving production efficiency. Compared with traditional single-station machines, the double-station design reduces waiting time and achieves seamless connection of the production process, allowing enterprises to take the lead in the fierce market competition.

The machine adopts an advanced PLC control system and is equipped with a human-machine interface display to achieve real-time monitoring and precise control of the production process. Whether it is temperature, pressure or blow molding time, it can be accurately adjusted through the system.

Double station extrusion blow molding machine is not only suitable for the production of daily necessities such as medicine bottles, food cans, and cosmetic containers, but can also easily cope with the manufacturing needs of large-capacity containers such as detergent bottles and mineral water bottles. Its multi-level co-extrusion function meets the market’s pursuit of high-performance products such as environmental protection and durability. Whether it is PE, PP, or PVC, the machine can easily cope with it, showing strong adaptability and flexibility.

While pursuing efficient production, double station extrusion blow molding machine also pays attention to energy conservation and environmental protection. Its optimized screw, barrel, and variable frequency speed control motor drive system effectively reduce energy consumption and noise pollution. At the same time, these designs not only reduce production costs, but also win a good social reputation for the company.

The machine is also equipped with a complete intelligent maintenance system that can monitor the operating status of the equipment in real time and warn of potential faults in advance. You can easily set various parameters and view real-time data through the touch screen, which greatly reduces the difficulty of operation and maintenance costs.

Double station extrusion blow molding machine has become a leader in the plastic processing industry with its excellent performance, efficient production capacity and wide application fields. It not only brings significant economic and social benefits to enterprises, but also contributes to the transformation and upgrading and sustainable development of the entire industry. Choosing double station extrusion blow molding machine means choosing an efficient, intelligent and environmentally friendly future production model.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign