Recently, the Stone Plastic Paper Making Production Line (referred to as Stone Plastic Paper Making Machine) exported by TINCOO to Shahrud City, Semnan Province, Iran has completed installation and commissioning, and officially started production at 11:00 am on February 2nd, 2022. The governor visited the factory to cut the ribbon. More than 60 people from local government, senior management of many companies, new investors and media came to visit our Stone Plastic Paper Making Production line.

This time, our company exported to Shahrud City Semnan province Iran Stone Plastic Paper Making Production Line specifications are as follows:

Width: 1200MM(MAX)

Thickness: 0.08MM-0.3MM(After stretching)

Material: LDPE, LLDPE, PP + Filler(60-80)%CaCO3

Output: 500KG/HR (Final Output is Subjected To the Formulation & Other Conditions)

The raw material of the Stone Plastic Paper Making Production Line is LDPE or LLDPE or PP+60%-80% calcium carbonate filler. Different from the traditional manufacturing process, the pulp needs to be treated to produce sewage, coal ash, sulfur dioxide and carbon monoxide emissions, which cause environmental pollution, the stone molding paper production line only needs a small amount of recycled cooling water. Its whole production process is low carbon, environmental protection, innovation, energy saving and more practical for environmental protection paper making.

This time, The Stone Plastic Paper Making Production Line of TINOO exported to Shahrud city, Semnan Province, Iran officially started production, promoting a new chapter of pollution-free papermaking, contributing to pollution-free work.

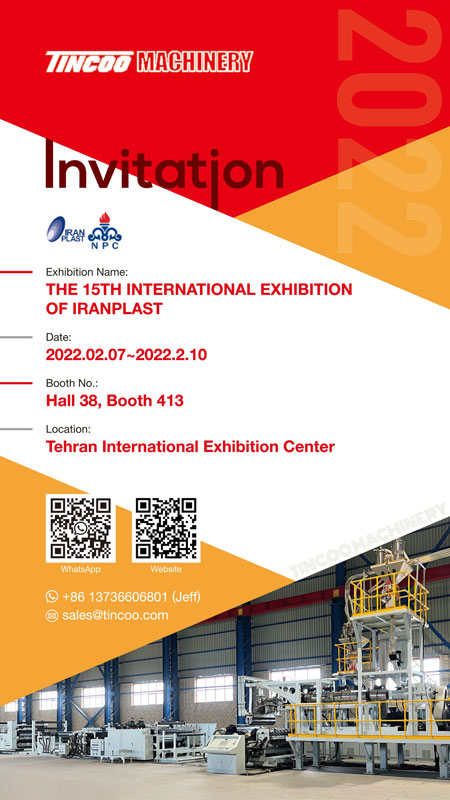

Our company will attend the 15th International Exhibition of IRANPLAST in Teheran from February 7 to 10, 2022, exhibition Hall 38, booth 413, welcome friends from all walks of life who are interested to visit.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign