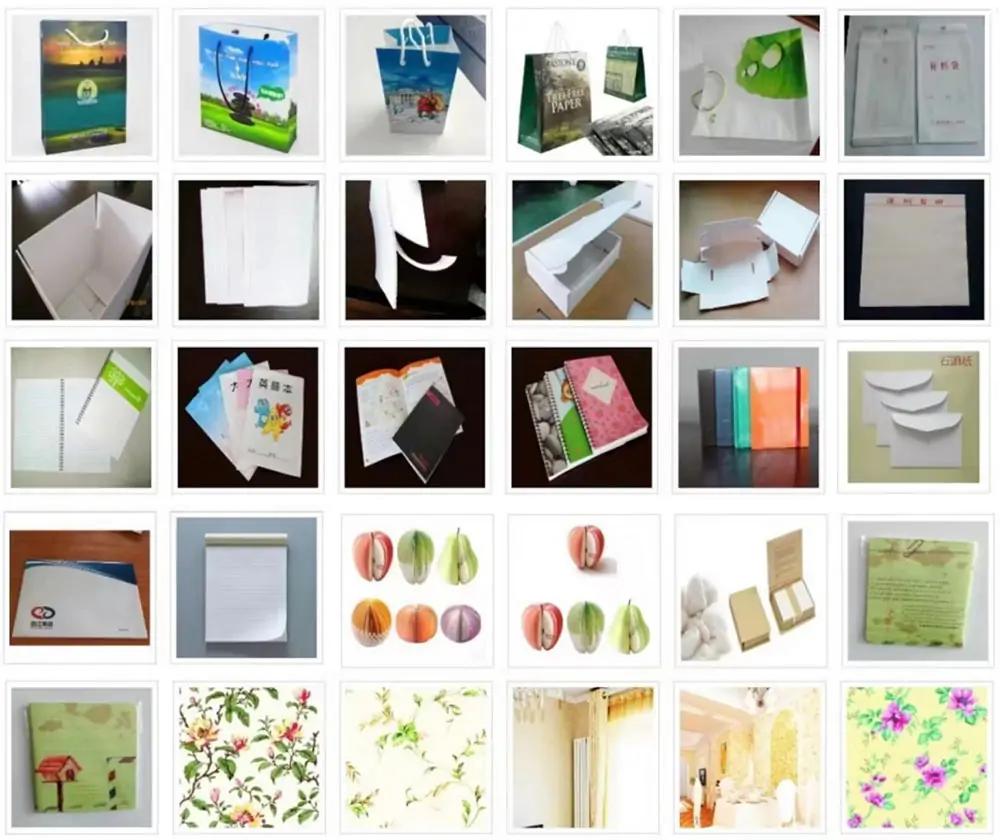

Superfine modified ore powder, superfine whitening stone powder and specific PE.PP and other additives are mixed in a strict ratio and mixed by a high-speed mixer, and then enter the filling masterbatch extrusion equipment for waterless mixing process, producing different types Filled masterbatch. All kinds of filled masterbatch pass through the stone paper carton paper after matching.

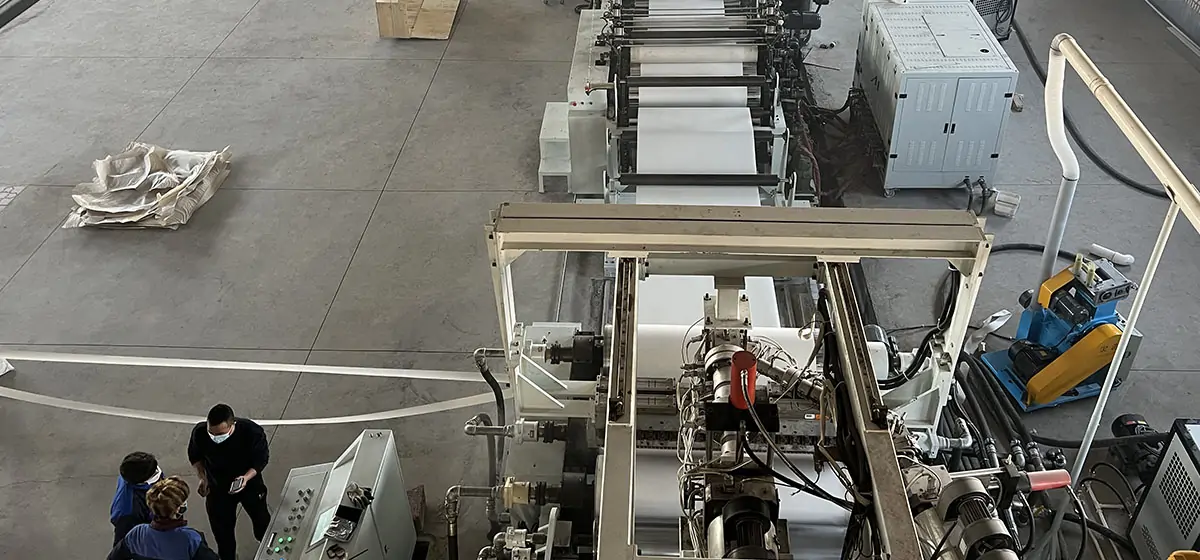

Stone paper equipment / production line to produce polymer stone-plastic composite boards and boxes; or to produce various types of base paper through different production processes through stone synthetic paper production equipment.

| DH-SPPM-75/125-1600 | |

| Material | LDPE,LLDPE, PP+filler(60-80)% CaCO₃ |

| Width | 1200MM |

| Thickness | 0.08MM(After stretching) |

| Extrusion output | 500KG/HR |

| Extrusion screw | ¢75MM/¢125MM, L/D: 32:1 |

| Drive motor | 100HP/215HP AC motor (TECO)+ vector inverter controller (Yaskawa) |

| Layer assignment | A/B/A=10/80/10 (%) and A/B/B=20/40/40 (%) |

| Extruder Die | T type, 1600MM width |

| Machine speed | 100M/MIN |

| Winding device | Biaxial round tower center winding |

| Coiling maximum diameter | 1000MM (MAX) |

What kind ok the service you can grt from us.

280kwH power can be saved for 1 ton stone paper production compared with the traditional fiber paper production .

The stone paper production course actually is modification working course. Small quantity cooling water is recycled during this period. So, much water consumption is saved. Compared with the traditional fiber paper , 110-130 ton fresh water can be saved for 1 ton stone paper producing. It is a special contribution to relax the nervous water resource situation.

Stone paper production is a course of no-water, no-steam, no-wood pulp . Stone powder ,resin and small quantity additives as its raw materials. It is very different from the traditional paper making plant which needs heavy equipment, large storage space for woods and other plant fiber materials. Working area is only 1/10 of the traditional paper making plant.

Much waste water discharge during the traditional paper making course, which will spend big capital for its non-skilled clearing technology and harmful to social environment.. Only cooling water in the barrels is needed for stone paper production, no any environment pollution. So stone paper production is also a project with environment protection project.

What is machine to make paper?

To make paper, you will need a machine to make paper. This machine is used to turn pulp into paper. The pulp is made from wood chips, recycled paper, or other materials. The papermaking machine will mix the pulp with water and then press it into sheets. The sheets are then dried and cut into the desired size.

Learn More